◉Project Name - Giant aluminum trusses for greenhouse plantations of Indonesian Agriculture Bureau

◉City - Indonesia

◉Products

◉Project Profile

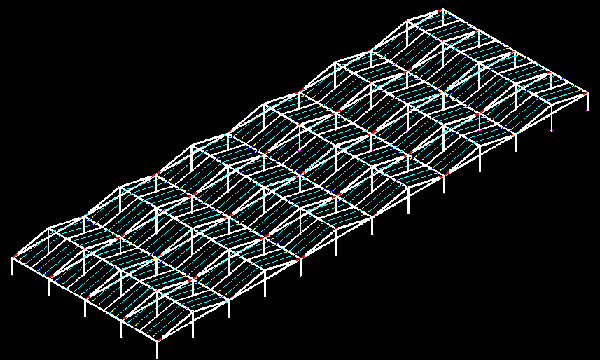

In 2016, the agricultural department of the Indonesian government initiated a groundbreaking venture by establishing a smart greenhouse planting test garden, aiming to foster advancements in agricultural technology, guarantee food security, and drive the sustainable development of agriculture. To bring this vision to life, the department issued a public tender for an expansive greenhouse truss spanning an area of 10,800 square meters, with dimensions of 180 meters in length, 60 meters in width, and a towering height of 6.6 meters. Mr. Martin emerged as the fortunate entrepreneur who secured the winning bid for this ambitious project.

To fulfill the project's requirements, Mr. Martin had to exercise meticulous control over the procurement budget, which involved a thorough process of visiting and engaging in negotiations with numerous suppliers. Mr. Martin held a steadfast belief that for a project of this magnitude, compromising on profits was a necessary evil to ensure unwavering quality. After a rigorous comparison of the qualifications and product offerings of various suppliers, he made the strategic decision to enter into a procurement contract with Sgaier Truss.

The choice was influenced by Sgaier Truss's rich repository of project experience, their commitment to using genuine materials, their stringent product quality supervision, their exceptional welding technology, and their significant investment in material costs. This commitment to quality was attributed to the company's advanced production quality management system and their meticulous attention to the integrity of their materials. In contrast, many of the suppliers Mr. Martin had assessed were found to use mixed materials, resulting in inconsistent quality standards among finished products within the same batch.

Convinced that quality should be the paramount consideration, Mr. Martin resolutely opted to align himself with excellence. He designated Sgaier Truss as the sole supplier of the greenhouse aluminum alloy truss for this project, a decision that reflected his dedication to upholding the highest standards of quality and ensuring the success of the innovative smart greenhouse planting test garden.

◉Customer Needs

Mr. Martin needed a giant greenhouse truss of 10,800 square meters with a length, width and height of 180*60*6.6 meters. The order quantity was large, the product quality standard was high, and the delivery cycle was short, which was a huge challenge for any supplier. However, Mr. Martin knew that only by ensuring that these key factors were met could the entire project be completed on time and in quality, so as not to affect the planting trial plan of the government's agricultural bureau.In addition to providing factory quality inspection, the supplier also sends senior engineers to conduct on-site surveys, drawings, and installation guidance to ensure safe and quality construction.

In order to meet this challenge, Mr. Martin adopted the following strategies:

First, he carefully selected a group of suppliers with a high reputation in the industry. These suppliers not only have advanced production equipment and processes, but also have rich project management experience. Mr. Martin had several rounds of negotiations with them, elaborating in detail on the urgency and importance of the project, as well as his strict requirements for product quality.

Secondly, in order to ensure the delivery cycle, Mr. Martin worked with the supplier to develop a precise production schedule. In this schedule, each production link has a clear time node, including raw material procurement, processing, quality inspection, packaging and logistics. In addition, he also asked the supplier to reserve a certain buffer time to deal with possible unexpected situations.

In terms of quality control, Mr. Martin requires suppliers to strictly follow international standards for production and provide third-party quality certification. He also arranged his own quality supervision team to enter the supplier's production line to monitor the production process in real time to ensure that each truss meets the design specifications.

In order to improve production efficiency, Mr. Martin and the supplier jointly optimized the production process, adopted assembly line operations and automated equipment, and greatly increased the production speed. At the same time, he helped suppliers solve the problem of capital circulation through advance payments, enabling suppliers to organize production more quickly. Throughout the procurement process, Mr. Martin always maintained close communication with suppliers, kept abreast of production progress, and coordinated to solve various problems. His professionalism and decisiveness won the respect and trust of suppliers, making cooperation smoother.In the end, under Mr. Martin's careful planning and strict management, the order for giant greenhouse trusses was not only completed ahead of schedule, but also passed strict quality inspections. The supplier delivered all trusses on time.

◉Product Parameters

The final 10,800 square meters, 180*60*6.6 meters in length, width and height, giant greenhouse trusses were constructed using 1,000 meters of trusses. The specific parameters are:

Truss material: High-strength aluminum alloy 6061-T6 is used, which has good corrosion resistance and mechanical properties, ensuring the long-term stability and durability of the trusses.

Truss cross-sectional dimensions: The main beam is 300mm*400mm, the secondary beam is 300mm*300mm, and the wall thickness is 5mm, which ensures the load-bearing capacity and wind resistance of the structure.

Truss spacing: The main beam spacing is 6 meters, and the secondary beam spacing is 3 meters. This design not only ensures the stability of the greenhouse, but also provides sufficient support for internal planting.

Connection method: Bolt connection is adopted, and each connection point is equipped with anti-loosening gaskets and anti-corrosion coatings to ensure the firmness and durability of the connection.

Surface treatment: The surface of the truss is anodized to increase corrosion resistance, while providing a smooth appearance for easy cleaning and maintenance.

Earthquake-proof design: Considering the frequent earthquakes in the local area, the truss structure is designed with elastic connections and shock-absorbing nodes to absorb earthquake energy and reduce the impact of vibration on the greenhouse.

Wind-proof design: The truss structure has been simulated and tested to withstand the local maximum wind speed of level 7, ensuring the safety of the greenhouse in bad weather.

Thermal insulation performance: The truss is filled with thermal insulation materials to reduce heat loss, maintain a constant temperature environment in the greenhouse, and is conducive to plant growth.

The 1,000-meter truss uses high-strength, corrosion-resistant special alloy materials to ensure the stability and durability of the greenhouse. In terms of design, the team adopted a modular structure, which enables the truss to be quickly assembled and disassembled, greatly improving construction efficiency. Each module has been carefully designed to withstand the pressure of the external environment and ensure full utilization of the internal space.

During the construction process, Mr. Martin personally supervised to ensure that every meter of truss was installed in place strictly in accordance with the design drawings. In order to cope with possible natural disasters such as strong winds and earthquakes, the team also added additional reinforcement measures, including strengthening node connections and adding support structures.

After the installation, the giant greenhouse has a smooth appearance and modern design, becoming a highlight of the local agricultural technology demonstration. The interior is divided into multiple functional areas, including planting area, test area, storage area and office area. Each area is equipped with an advanced automatic control system to achieve precise control of key growth parameters such as temperature, humidity, light, and carbon dioxide concentration.

◉On-site effects

◉Customer Reviews

After nearly a year of hard work, we successfully completed the construction of the giant greenhouse. After the project was accepted, the smart greenhouse planting test garden was officially put into operation. The success of this project not only brought huge profits to the company, but also contributed to the advancement of agricultural technology and sustainable development in Indonesia. The company has therefore been highly praised by the government and all sectors of society.

Contact Us Today

12

Founded 12 years ago

155

Exported to 155 countries

12600+

Served 12600+ customers

10000

Built a 10,000 ㎡ automated factory